Does anyone have any drawings of bow fingers for a press I want to build. I have a buddy that is willing to make them for me. He runs a metal shop. I just need to get him some plans to get started. I would think you can modify the LCA or other press fingers and they can't say anything. Am I thinking correct?

Girvin13

Bow press finger detailed drawings?

Girvin13

Discussion starter

31 posts

·

Joined 2017

- Add to quote Only show this user

Does anyone have any drawings of bow fingers for a press I want to build. I have a buddy that is willing to make them for me. He runs a metal shop. I just need to get him some plans to get started. I would think you can modify the LCA or other press fingers and they can't say anything. Am I thinking correct?

23 posts

·

Joined 2019

23 posts

·

Joined 2019

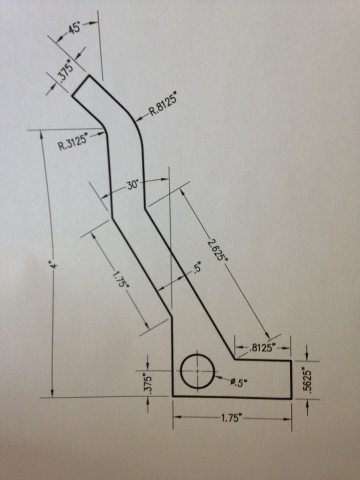

I did run into a hiccup with the above design though. I did not leave enough room between the 1/2" hole and the front edge of the finger to drill a hole for the coil spring to support the finger in the upright position. I ended up using high tensile steel banding strap as a flat spring screwed to the front of the fingers. I also changed from a welded center block to short angle iron end brackets.

51 posts

·

Joined 2022

Looking to build a press. I can make the fingers. But since the concept is the same but the height vary’s from design to design. And I’ve NEVER used a press before I want to make sure I build the correct fingers.

I’m buying the Mathews atlas. Can anyone that has pressed this bow or know for sure what fingers to build. Thank you

I’m buying the Mathews atlas. Can anyone that has pressed this bow or know for sure what fingers to build. Thank you

17,160 posts

·

Joined 2017

Any of those above would work, however I'd recommend having a round tip instead of square like the drawing above. Your bow will only contact the press at the tip of the finger and the recess in the little metal piece on the end of the limb.

23 posts

·

Joined 2024

FYI, I stumbled across this thread in a search and decided to work from the information presented. I recreated the dwg shown above by pasting the graphic into AutoCAD and then tracing over it (more or less...the numbers don't match the actual line dwg). Then I exported it to a .dwx file and sent it to Send Cut Send for a quote. They'll make 4 of these out of 1/2" mild steel for under $40 (including tax and shipping), which is HALF what the Ebay sellers are asking for these nowadays. I did have to move the 1/2" dia hole a bit inboard on both axis, to accommodate SCS's waterjet limitations, but I think that's probably a better design anyway. I also changed the tips to 3/8" dia round curves, to match the factory indents on my Matthews Phase 4 limbs.

7 posts

·

Joined 2018

FYI, I stumbled across this thread in a search and decided to work from the information presented. I recreated the dwg shown above by pasting the graphic into AutoCAD and then tracing over it (more or less...the numbers don't match the actual line dwg). Then I exported it to a .dwx file and sent it to Send Cut Send for a quote. They'll make 4 of these out of 1/2" mild steel for under $40 (including tax and shipping), which is HALF what the Ebay sellers are asking for these nowadays. I did have to move the 1/2" dia hole a bit inboard on both axis, to accommodate SCS's waterjet limitations, but I think that's probably a better design anyway. I also changed the tips to 3/8" dia round curves, to match the factory indents on my Matthews Phase 4 limbs.

Hello. Do you or thay company still have the file for the fingers? I'm trying to build a press and don't really want to spend 85 plus shipping from ebay. ThanksFYI, I stumbled across this thread in a search and decided to work from the information presented. I recreated the dwg shown above by pasting the graphic into AutoCAD and then tracing over it (more or less...the numbers don't match the actual line dwg). Then I exported it to a .dwx file and sent it to Send Cut Send for a quote. They'll make 4 of these out of 1/2" mild steel for under $40 (including tax and shipping), which is HALF what the Ebay sellers are asking for these nowadays. I did have to move the 1/2" dia hole a bit inboard on both axis, to accommodate SCS's waterjet limitations, but I think that's probably a better design anyway. I also changed the tips to 3/8" dia round curves, to match the factory indents on my Matthews Phase 4 limbs.

22 posts

·

Joined 2005

Any of the fingers here should press the Atlas without a problem. I've used shop made fingers as well as last chance fingers. They both worked just fine.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 39M

- members

- 242K

- Since

- 2001

A forum community dedicated to bow and crossbow owners and archery enthusiasts. Come join the discussion about optics, hunting, performance, troubleshooting, styles, reviews, accessories, classifieds, and more!

Our Vendors

View AllTop Contributors this Month

View All

toddcbrown

542 Replies

Mossy-Back

444 Replies

Alaska at heart

337 Replies